Our sites have an own developed automatic vehicle weighbridge system designed and installed to measure products and transport vehicles quickly and accurately for faster and more convenient administration.

How the weighbridge works...

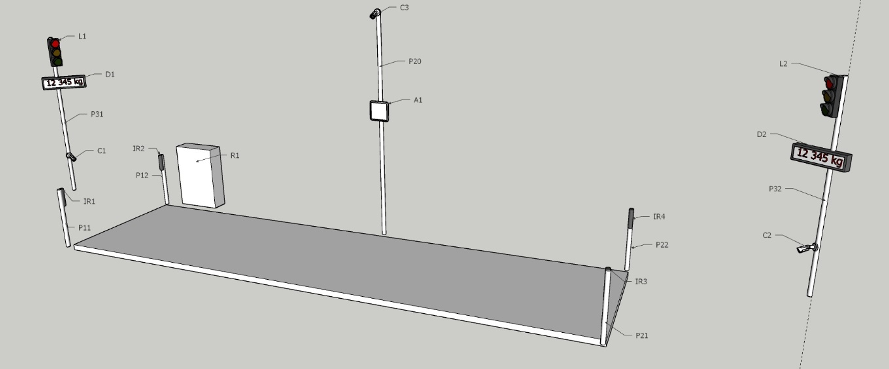

The vehicle weighbridge is accessible by vehicles from both directions.There is a red-yellow-green traffic light on each side, a number plate recognition camera on each side, a cargo camera and RFID reader mounted on a pillar in the middle of the weighbridge. At some sites, the actual weight measured can also be read on an LED display (optional).

Weighing stages:

- 1. Drive up

- 2. Setting the stable weight

- 3. Storing photos, registration numbers and weight

- 4. Drive off

Traffic light signals:

- Yellow flashing: the system is operating, you can drive up- Yellow steady light: the weight of the train has exceeded the set 2 tonnes, waiting for the stable weight to be set

- Red: photos being taken, data being saved to database

- Green: vehicle can be driven off the scale

Schematic drawing of the system

Important!

- The measurement should always be taken together with the driver, and the driver should preferably not get out of the vehicle before the light turns green!

- If the logistics are planned that way and is possible, always weigh the complete vehicle trailer when empty, and also with load!

- If the trailers are loaded separately, be sure to weigh only the tractor itself before the tractor coupling the semi-trailer!

- The trailers must be weighed at least every six months! 1

- Avoid driving quickly over the scale! It's better to have unnecessary weighings than missed ones!

1 for own fleet of vehicles only